3.13

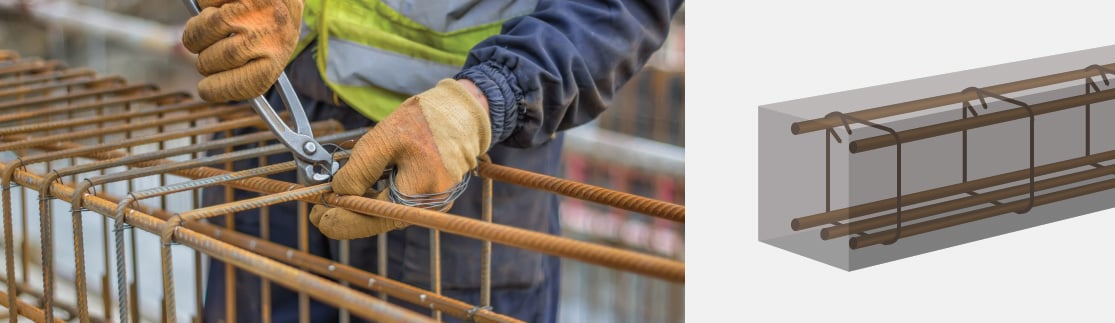

Reinforcement

Designer

- Details of reinforcement; bar size, spacing, arrangement

- Fabric reinforcement ; mesh , type etc.

- Special reinforcement (e.g. galvanized, stainless etc.)

- Fibre reinforcement (steel, polypropylene )

- Prestressed?

- Connections ( lap length, connectors etc.)

- Anchorages, couplers etc.

- Welding restrictions

- Cover (see also page 3.3)

- Check detailing for ease of placement

Builder

- Storage arrangements

- Handling, cutting, bending etc.

- Fixing

- Spacers, chairs etc.

- Impact of congested reinforcement on concrete placing

- Prefabrication of rebar cages – columns, piles, walls etc

- Prefabrication of rebar cages – temporary works design for lifting

- Tying

- Splices, couplers

-

- Is re-bending of bars on site permitted – (Class A, B or C bars)

- CARES certificates

Producer

- Impact of congested reinforcement on concrete mix design – workability, maximum aggregate size etc.

- Addition of fibres to readymix truck ; type, dosage rate

- Effectiveness of mixing

Further Guidance

Main Standards – Reference

I.S. EN 10080

I.S EN 13670

Clause 6 & Annex D